- Number of MWPC: 1368; of 3-GEM: 24 (Station M1, Region R1)

- Four gap chambers in Stations M2-M5. Two gap in M1 (R2-R4).

- Gas gap: 5 mm

- Wire: Gold-plated Tungsten, 30 mm dia.

- Wire spacing: 2 mm

- Wire length: 250 to 310 mm

- Wire mechanical tension: 60 gf

- Total number of wires: ~ 3 Million

- Gas mixture: Ar/CO2/CF4 (40:50:10)

- Gas gain: G ≈ 105

- Charge/mip: ≈ 0.8 pC @ HV ≈ 2.7 kV

- Field on wires: 262 kV/cm, on cathodes 6.2 kV/cm

- Gain uniformity: ≤ 30%

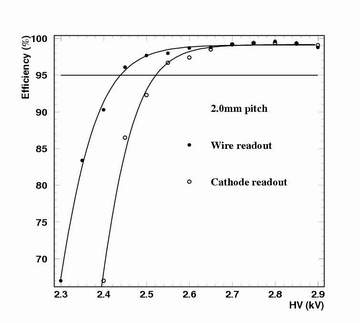

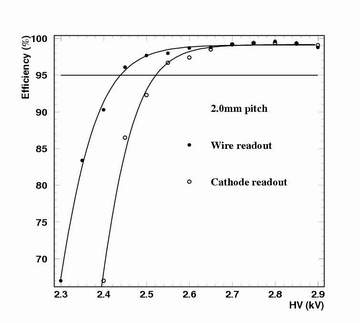

- Gap efficiency: ≥ 95% in 20 ns window ( st ≈ 3.9 ns)

- Rate/channel: max 2 MHz in M1, < 0.6 MHz M2-M5

- Max. operating voltage: 3 kV

|

Typical efficiency plateau for two gaps in OR (double-gap)

|

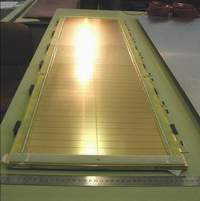

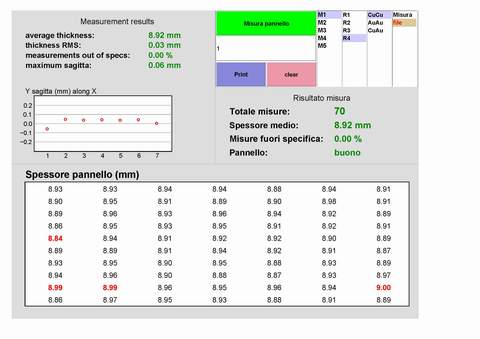

Final Source and Cosmic Rays Test before installation (July 2006)

Final Source and Cosmic Rays Test before installation (July 2006)